Overview

An Optical Turbidity Sensor, also referred to as an Optical Turbidity Probe, is a sensor designed to measure the turbidity level in liquids by analyzing how light interacts with suspended particles. Turbidity is a critical parameter in water quality monitoring, as it reflects the presence of contaminants such as sediments, microorganisms, and organic matter. Accurate turbidity data is essential for environmental protection, process control, and compliance with regulatory standards in water and wastewater management.Â

Optical Principles: Infrared and Laser Scattering Technologies

The optical measurement method employed by turbidity sensors is based on the interaction of light with particles in the water. Two common optical principles are used. The first is infrared light scattering at a wavelength of 860 nm, where the sensor emits infrared light and measures the light scattered by particles at specific angles. This method is widely used due to its immunity to color interference and its compliance with the ISO 7027 standard. It ensures stable and reliable readings in a variety of conditions.Â

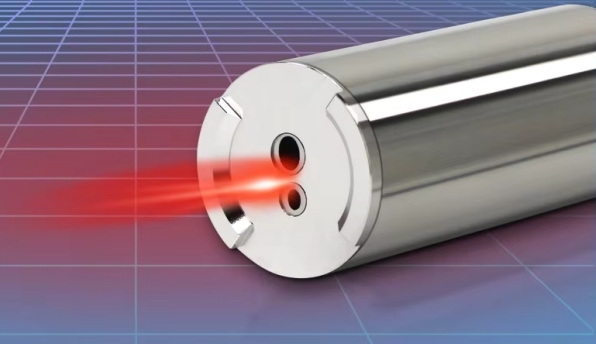

The second principle uses laser scattering, typically at a wavelength of 660 nm. Laser-based turbidity sensors offer higher sensitivity and can detect extremely low turbidity levels. They are ideal for applications where high-resolution measurement is required, such as in ultrapure water monitoring or quality control in beverage production. The narrow beam of laser light improves measurement focus and minimizes background noise.Â

Â

Key Features and Advantages

Optical Turbidity Sensors provide several technical benefits compared to traditional nephelometric or manual sampling methods. They offer continuous real-time measurement, high precision, and low maintenance due to their contactless optical design. Many models are equipped with automatic cleaning systems—such as wipers or ultrasonic cleaners—to prevent fouling and maintain long-term accuracy. Optical sensors also demonstrate strong stability over time and resistance to environmental drift, making them suitable for harsh operating environments.Â

Additional advantages include digital output compatibility (such as RS485 with Modbus protocol), user-configurable calibration, and robust sensor housing made from corrosion-resistant materials like stainless steel or PVC. These features enhance their adaptability in both portable and fixed installation systems. Integration with SCADA or PLC systems is straightforward, enabling automated control and data logging.Â

Typical Applications

Optical Turbidity Sensors are widely used across various industries and environmental applications. In municipal water treatment plants, they monitor the clarity of drinking water and the performance of filtration units. In wastewater treatment facilities, they track effluent quality to ensure regulatory compliance. The aquaculture industry uses turbidity monitoring to maintain optimal living conditions for aquatic species by controlling feed residues and suspended solids.Â

In industrial processing, such as in food and beverage production or chemical manufacturing, Optical Turbidity Sensors help control process water clarity and product consistency. Environmental agencies and research institutions also deploy these sensors for river and lake monitoring, sediment transport studies, and climate-related water quality assessments. Their flexibility and accuracy make them essential tools in modern water quality management systems.Â

Â

Conclusion

When precision and reliability are critical, Daruifuno Optical Turbidity Sensors deliver proven performance. Built on advanced optical measurement technologies, our sensors are engineered for accuracy, durability, and operational efficiency. We offer cost-effective pricing without compromising quality. All models support OEM and private labeling, and we provide customized solutions to meet unique technical or industrial needs.Â

Daruifuno is committed to providing professional-grade sensors that integrate easily into your systems and meet international standards. Whether for regulatory monitoring or industrial process optimization, Daruifuno ensures that your turbidity measurements remain accurate and consistent over time.

Optical Turbidity Sensor, Optical Turbidity Probe, infrared turbidity sensor, laser turbidity sensor

Suzhou Delfino Environmental Technology Co., Ltd. , https://www.daruifuno.com