Brass is an alloy primarily composed of copper and zinc, sometimes mixed with additional metals. On the other hand, stainless steel is an iron alloy containing chromium and nickel. While brass is less costly compared to stainless steel, steel offers superior durability and resilience. Stainless steel can function effectively across a broader range of temperatures and typically lasts longer than brass. Both stainless steel ball valves and brass ball valves are corrosion-resistant, but stainless steel ball valves stand out as the optimal choice for high-pressure and high-temperature scenarios.

Ball valves are widely utilized in the plumbing industry for their ability to halt the flow of water in pipelines. There are two primary materials used for metal ball valves: brass and stainless steel. As stainless fittings gain traction in non-industrial applications, stainless steel ball valves are increasingly being recognized for their versatility and strength.

1. What Are Stainless Steel Ball Valves?

A stainless steel ball valve can be securely closed with just a 90-degree rotation and minimal torque. Its internal cavity ensures a smooth, unobstructed flow path, minimizing resistance for the medium passing through. One of the standout features of a ball valve is its compact design, making it simple to operate and maintain. These valves are capable of controlling the flow of various fluids, including air, water, steam, corrosive media, mud, oil, liquid metals, and radioactive substances. The valve body can be either integrated or assembled. Typically, these valves are installed horizontally within the pipeline. The two most common materials used for stainless steel ball valves are 304 and 316.

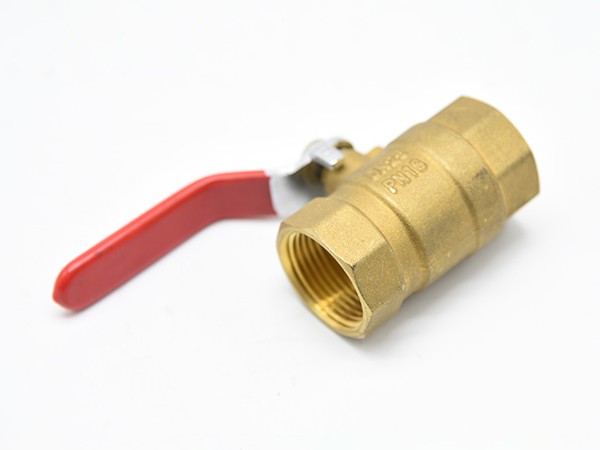

2. What Are Brass Ball Valves?

Brass ball valves are among the most frequently used in plumbing, water wells, and similar applications. They are relatively easy to handle and install, making them suitable for situations where corrosion resistance isn’t a major concern. Brass ball valves are straightforward to work with due to the softness of brass compared to other materials like stainless steel. This softness simplifies the sealing process. Additionally, since brass valves are widely used, the necessary sealing products are readily available. Sealing other types of metals often requires specific pipe tapes or sealants, which can be harder to find compared to brass sealing products.

3. Applications For Stainless Steel Ball Valves

Given their corrosion resistance, high-temperature tolerance, and ability to handle high pressure, stainless steel ball valves are extensively used in industries, manufacturing, construction, and pipelines.

Here are some common application areas for stainless steel ball valves:

Petroleum Refining

This is a perfect example of a task where only stainless steel ball valves can excel. Crude oil often contains water, carbon dioxide, sulfur, and various microorganisms, making it highly corrosive. Over time, such substances degrade metal components, so valves and pipes must be resistant to corrosion. Stainless steel ball valves offer greater longevity than other materials, making them the preferred choice.

Marine Operations

Applications involving seawater, such as desalination, present a challenging environment for materials. Marine settings are particularly corrosive, affecting all materials, especially metals. Although plastic ball valves might seem appealing due to their resistance to water and harsh chemicals, they lack the strength to handle high pressures and extreme temperatures. Stainless steel ball valves, however, can withstand such intense conditions effortlessly. With proper maintenance, these valves can last a long time even in seawater environments.

Brewing Systems

Stainless steel ball valves are essential in almost every brewery. Commonly placed on kettles, these valves enable users to control liquid flow during transfers. The necessity of stainless steel arises because the wort, a corrosive liquid produced during the brewing process, would damage valves made from iron. Other materials like brass ball valves cannot handle the high temperatures encountered in brewing, making stainless steel the ideal choice.

4. Applications For Brass Ball Valves

Brass ball valves are versatile and suitable for numerous applications. They are commonly used in residential and commercial plumbing, water wells, HVAC systems, and many other fields. Essentially, brass is a great option as long as the medium flowing through the valves doesn’t have highly corrosive properties.

In potable water applications, No-Lead Brass is often recommended unless the water is highly corrosive, such as seawater with high salt content. In such cases, materials like stainless steel are preferable. Due to the rising cost of No-Lead Brass, other materials like stainless steel, which is also No-Lead, are becoming viable alternatives.

5. Differences Between Stainless Steel Ball Valves and Brass Ball Valves

- Material: Brass ball valves are a copper alloy containing copper and zinc, occasionally mixed with other metals. Stainless steel ball valves, however, are an iron alloy with chromium and nickel.

- Cost: With the introduction of No-Lead laws in many regions, No-Lead Brass gained popularity, driving up its prices. Stainless steel ball valves are more expensive than leaded brass ball valves, but the cost difference between leaded and lead-free brass ball valves is negligible. Using lead-free brass ball valves in non-potable water applications can be a cost-effective choice.

- FDA Approval: The FDA does not approve brass ball valves unless they are certified lead-free, making them unsuitable for food industry applications. Stainless steel ball valves, however, are FDA-approved for food industry use.

- Softness: Brass is softer than stainless steel, making it easier to seal brass ball valves compared to stainless steel ball valves. Products for sealing brass ball valves are more readily available than those for sealing stainless steel ball valves. Brass is better suited for welding than stainless steel, which often requires breaking down its oxide layer before welding.

- Corrosion Resistance: Brass is more resistant to corrosion than plastic. However, stainless steel remains the best in terms of corrosion resistance, especially in marine environments. Stainless steel ball valves perform better in harsh water conditions, ensuring longer-lasting performance.

- Pressure Ratings: Generally, stainless steel ball valves have higher pressure ratings than brass ball valves. For instance, a standard brass ball valve might have a pressure rating of 600 PSI for a 1-inch model, whereas a standard stainless steel ball valve would likely have a pressure rating of 1000 PSI for the same size. Thus, stainless steel ball valves are more resistant to high pressure than brass ball valves.

- High-Temperature Resistance: Stainless steel can operate in a wider range of temperatures than brass and tends to last longer. Stainless steel ball valves are the best choice for high-temperature scenarios.

When selecting valve materials for your projects, consider these factors carefully. Always conduct thorough research into your industry, requirements, and preferred materials before choosing a valve. Remember that if enhanced corrosion resistance is desired, a full stainless steel system is recommended.

SANVO is a reputable manufacturer and supplier of quality stainless steel ball valves in China, exporting 1/4" to 4" and DN6 to DN100 sizes of 304/316 stainless ball valves. SANVO is also a leading manufacturer and supplier of carbon steel and stainless steel pipes, fittings, and flanges in China.

If you're interested in our pipeline products, feel free to contact us. We look forward to hearing from you.

Accessibility And Safety Probes

Accessibility and Safety Probes

Guangdong Yuwei Testing instrument Co., Ltd , http://www.yuweiinstrument.com